Product Category

Contact Us

Contacts:James

Whatsapp:+86 18857712033

Tel:+86 18857712033

Fax:+86-577-65160712

E-mail:sales@xinxin-flexo.com

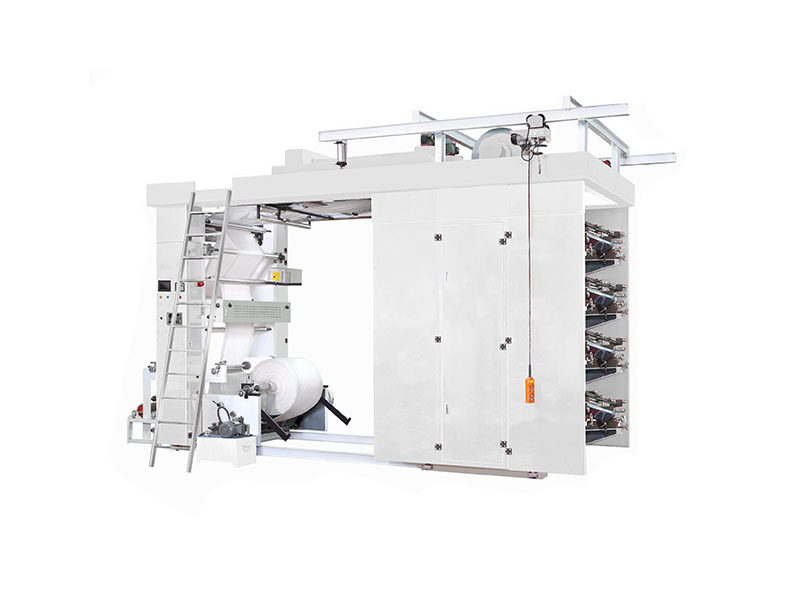

6 color flexo printing machine

This flexographic printing machine uses PLC to control the whole machine, with hydraulic automatic loading and unloading. Colour registration is precise, easy to operate and highly automated. It is suitable for printing on roll materials and is ideal for printing on food paper bags, plastic bags, woven bags etc.

Classificar:

Keywor:

printing machine

Flexographic press

E-mail:

- 产品描述

- Description

- Application

- Option

- Shippment

-

- Commodity name: 6 color flexo printing machine

- Commodity ID: 08

This flexographic printing machine uses PLC to control the whole machine, with hydraulic automatic loading and unloading. Colour registration is precise, easy to operate and highly automated. It is suitable for printing on roll materials and is ideal for printing on food paper bags, plastic bags, woven bags etc.

Flexographic printing presses use fluid inks with high fluidity. The ink is transferred to the graphic part of the plate by an ink hopper roller and a mesh roller. The printing pressure is then applied by a press roller to transfer the ink from the plate to the substrate.

Flexographic printing press mainly consists of four parts, namely, unwinding feeding part, printing part, drying part and rewinding receiving part. In modern flexographic press, there are generally tension control, edge control, alignment control, printing observation and other measurement and control devices and mechanical condition monitoring and fault diagnosis system. In addition, in order to expand the scope of application, some flexographic presses are also equipped with glazing, laminating, gilding, slitting, die cutting, punching, screen printing, gravure printing unit and other devices, becoming flexographic joint production line.

Key words:- printing machine

- Flexographic press

-

This flexographic printing machine uses PLC to control the whole machine, with hydraulic automatic loading and unloading. Colour registration is precise, easy to operate and highly automated. It is suitable for printing on roll materials and is ideal for printing on food paper bags, plastic bags, woven bags etc.

Number of printing decks

ZYT(2/4/6/8) Substrate

Paper/ plastic / non-woven/ woven/ aluminum foil/ PET/ BOPP/ PE Max material width

800-2200mm (31.5-86.5 inch)

Max printing width

760-2160mm (29.5-85inch)

Max unwinding & rewinding diameter

Φ1300mm(51inch)

Max printing speed

100m/min

Printing repeat length

230-1000mm (9-39inch)

Registr precision

Longitude: ±0.15mm ; Transverse: ±0.2mm

Thickness of plate(include double-side tape)

(1.7 / 2.28 / 3.94)mm+0.38mm

Air shaft

3 / 6 inch

- PLC touch screen control of the whole machine, easy to operate.

- With automatic counting function, automatic stop when the number is reached and automatic stop when the material is broken.

- Hydraulic shaftless automatic unwinding, saving time and effort.

- Constant tension control system and side position control system, material tension is stable and does not run off.

- Diaphragm pump automatically absorbs ink, chamber doctor blade and ceramic anilox roller automatically circulate ink, ink is even.

- When the machine is stopped, the ink transport motor automatically drives the anilox roller to keep the anilox roller from clogging.

- Manual pressure adjustment, manual adjustment of the horizontal register, electric adjustment of the vertical register, with an accuracy of ±0.15MM.

- Intelligent temperature control, good drying effect.

- Roller friction winding, pneumatic control of winding tension, hydraulic automatic unloading.

- Translated with www.DeepL.com/Translator (free version)

Machine Printing Application

-

-

In addition to the standard configuration of the machine, we also offer various options and customisation services to meet the needs of our customers, as detailed in the table below.

1

video inspection

2

Slitting equipment 3

overhead crane

4

Corona processor 5

Refueling without stopping 6

Sleeve plate roller 7

Full servo motor drive (printing speed 240m/min) 8

Non-standard custom service -

The products will be wrapped in plastic film and shipped to their destination by sea or by the means specified by the customer. Please see the table below for the dimensions of the container required to transport the machine.

GYT 2 Color all model

20GP

GYT 4 Color all model

40GP

GYT 6 Color all model

40HQ

ZYT 2 Color all model

40GP

ZYT 4 Color all model

40HQ

ZYT 6 Color all model

40HQ

MESSAGE

Mobile website

Contact Us

Contacts:Alen Zhao

WeChat/Whatsapp:+ 86 18857712033

Mobile:+86 18857712033

E-mail:sales@xinxin-flexo.com

Add:No. 511, Development Zone Avenue, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

Fax:+86-577-65160712